The construction industry is in the middle of a quiet revolution, and at the heart of it is cold formed metal framing. Once thought of as a niche alternative to wood or hot-rolled steel, this system has quickly become the go-to choice for engineers, contractors, and architects who want efficiency, strength, and sustainability all in one package. For anyone managing projects in today’s competitive market, understanding how cold formed steel framing works isn’t just helpful—it’s essential.

What Makes Cold Formed Metal Framing Different?

At its core, cold formed metal framing is steel that’s rolled into shape at room temperature, creating precise, lightweight, yet high-strength structural profiles. Unlike hot-rolled steel, which requires massive energy inputs, cold rolling delivers tighter tolerances and cleaner finishes. Compared to traditional wood, it resists warping, termites, and fire risks. It’s no wonder that residential builders, high-rise developers, and even those tackling industrial-scale projects are making the switch.

The industry trend speaks for itself: light gauge steel framing, galvanized steel framing, and pre-engineered metal buildings are scaling up in demand. What started as a solution for non-load-bearing partitions has expanded into curtain wall framing, metal roof trusses, and even load-bearing structural steel framing.

The Science Behind the Strength

Cold formed steel profiles are made from high-grade sheet steel, typically galvanized to resist corrosion. This translates into durability that stands up against weather, moisture, and decades of use. Engineers value the superior strength-to-weight ratio—it’s lighter to transport and install, yet capable of handling massive loads when designed properly. Whether you’re dealing with load-bearing metal studs or intricate steel joist systems, cold formed metal framing offers unmatched consistency and reliability.

Engineering and Design Advantages

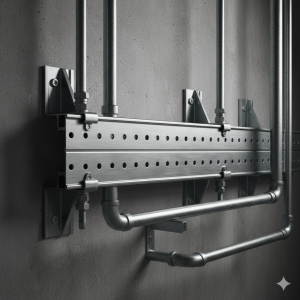

For design professionals, the possibilities with cold formed metal framing are wide open. Its modularity means that framing systems can be engineered to precise specifications, ensuring compliance with stringent building codes while leaving room for creative architectural expression. Connection systems, fastening technology, and integration with other metal building systems have also advanced, making it easier than ever to design with confidence.

This is not just about structural integrity—it’s also about speed to market. With prefabricated options, assemblies can be delivered to job sites ready for installation, drastically reducing time in the field. That’s a game changer for contractors managing tight schedules and budgets.

Installation: Precision Meets Efficiency

For installers, cold formed metal framing offers predictability. The material doesn’t twist, bow, or split, making every stud, joist, and track consistent. With the right tools—screw guns, cutting shears, and fastening systems—the process is straightforward. Teams can work faster, safer, and with fewer callbacks for rework. Quality control is easier, inspections run smoother, and overall labor efficiency skyrockets.

When compared to wood or traditional hot-rolled steel, this translates into tangible savings in time, labor costs, and project management headaches.

Cost, ROI, and Long-Term Value

While some may look at the initial material cost and wonder if it’s worth the investment, the numbers tell a clear story. Cold rolled steel profiles typically deliver better cost efficiency when you factor in labor savings, reduced waste, and long-term durability. With less maintenance, fewer issues from moisture or pests, and a higher level of fire resistance, buildings framed with cold formed steel often generate lower lifecycle costs. For commercial developers and residential builders alike, the ROI is significant.

Why Steinco is the Partner of Choice

This is where Steinco Industrial Solutions, Inc. stands apart. As a trusted supplier of professional-grade framing systems, Steinco delivers not just products but complete solutions. Their portfolio includes everything from galvanized steel framing components to specialized Unistrut support systems. What makes Steinco unique is their ability to combine a robust product line with custom fabrication capabilities and hands-on technical support.

For project managers, facility engineers, and architects, that means peace of mind. Whether you’re building a high-rise, a distribution center, or a complex curtain wall system, Steinco ensures you have the right framing products, the engineering support, and the expertise to get it done right the first time.

The Future of Construction is Cold Formed

Cold formed steel framing isn’t just another option—it’s the future of modern construction. It checks the boxes on strength, efficiency, sustainability, and cost-effectiveness. And with innovators like Steinco Industrial Solutions, Inc. leading the way, construction professionals have the tools they need to deliver projects that perform better, last longer, and save money over the long haul.

For anyone serious about staying competitive in today’s construction landscape, investing in cold formed metal framing solutions isn’t just smart—it’s essential.